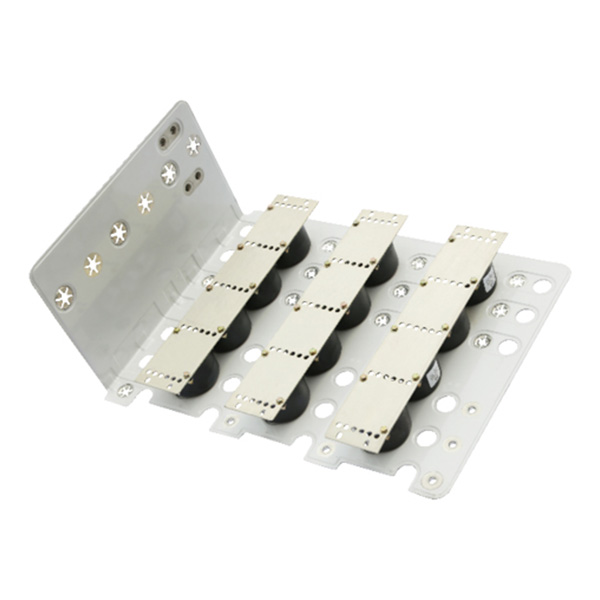

Laminated Busbar / Laminated Copper Busbar for Rail Traffic

Laminated busbar, also known as composite busbar, is called Laminated Busbar in English. It is a multi-layer composite structure connection bar, which can be regarded as the highway of the power distribution system. Compared with traditional, cumbersome, time-consuming and troublesome wiring methods, the use of composite busbars can provide modern, easy-to-design, fast to install and clearly structured power distribution system. It is a kind of fast high-power modular connection structural component characterized by repeatable electrical performance, low impedance, anti-interference, good reliability, space saving, simple installation.

- Insulation resistance20M Ω DC/1000V

- Parasitic inductance15nH/m

- Temperature rise≤30K

- Working temperature-40~105℃

Features of Laminated Busbar for Railway:

- Compact Design: Laminated busbars are designed to be compact, allowing for efficient use of space within the limited confines of railway vehicles.

- High Current Carrying Capacity: These busbars are capable of carrying high currents, ensuring the efficient distribution of electrical power throughout the train.

- Low Impedance: Laminated busbars have low impedance, reducing power losses and improving the overall efficiency of the electrical system.

- Temperature Resistance:They are designed to withstand the temperature variations experienced in railway environments, ensuring reliable performance under different operating conditions.

- Vibration and Shock Resistance: Laminated busbars are built to withstand the vibrations and shocks associated with railway travel, ensuring long-term reliability.

- Customizable Shapes and Sizes: Manufacturers can produce laminated busbars in various shapes and sizes to fit the specific requirements and space constraints of different railway applications.

- Insulation: The layers of laminated busbars are often insulated to prevent short circuits and ensure the safety of the electrical system.

Applications of Laminated Busbar for Railway:

- Power Distribution: Laminated busbars are used for distributing electrical power from the main power source to various components within the railway vehicle, including lighting, HVAC systems, traction systems, and more.

- Inverter Systems: They are employed in inverter systems that convert DC power from the overhead catenary or other power sources into AC power for driving electric traction motors.

- Battery Systems: In electric or hybrid trains, laminated busbars can be part of the power distribution network for battery systems, providing power for auxiliary systems and backup power.

- Control Systems: Laminated busbars play a role in distributing power to various control and monitoring systems, ensuring the seamless operation of the train.

- Efficient Energy Transfer: By providing a low-resistance path for electrical currents, laminated busbars contribute to efficient energy transfer, minimizing power losses during distribution.