Laminated Busbar for Wind and Photovoltaics Generation

Laminated busbars, also known as composite busbars, are multi-layered composite structures serving as the backbone of power distribution systems. Regarded as the expressways of electrical energy, they streamline and modernize power distribution compared to traditional, intricate, and time-consuming wiring methods. Utilizing composite busbars allows for the creation of a contemporary, easily designed, swiftly installed, and well-organized power distribution network.

- Insulation resistance20M Ω DC/1000V

- Parasitic inductance15nH/m

- Temperature rise≤30K

- Working temperature-40~105℃

Laminated Busbar / Laminated Copper Busbar for Rail Traffic

Laminated busbar, also known as composite busbar, is called Laminated Busbar in English. It is a multi-layer composite structure connection bar, which can be regarded as the highway of the power distribution system. Compared with traditional, cumbersome, time-consuming and troublesome wiring methods, the use of composite busbars can provide modern, easy-to-design, fast to install and clearly structured power distribution system. It is a kind of fast high-power modular connection structural component characterized by repeatable electrical performance, low impedance, anti-interference, good reliability, space saving, simple installation.

- Insulation resistance20M Ω DC/1000V

- Parasitic inductance15nH/m

- Temperature rise≤30K

- Working temperature-40~105℃

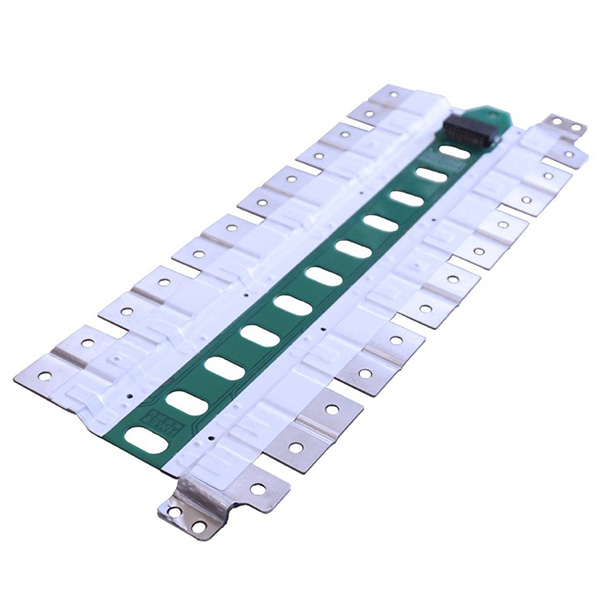

Laminated Busbar / Multi-layer Busbar for Inverter

Laminated busbar, also known as a composite busbar, is called a Laminated Busbar in English. It is a multi-layer composite structure connection bar, which can be regarded as the highway of the power distribution system. Compared with traditional, cumbersome, time-consuming and troublesome wiring methods, the use of composite busbars can provide a modern, easy-to-design, fast-to-install and clearly structured power distribution system.

- Insulation voltage300V-20KV

- Rated current0-4000A

- Insulation resistance20M Ω- infinity

- Temperature rise<40K

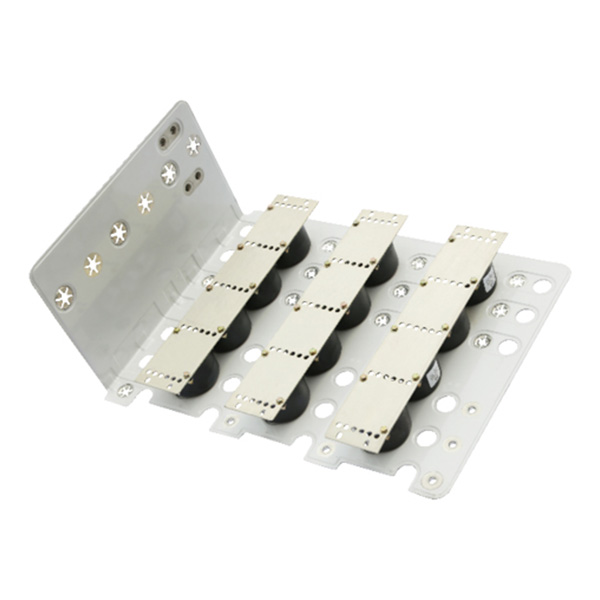

Laminated Busbar for Electric Car / Automative

A laminated busbar for an electric car refers to a component used in the electrical system of the vehicle. A busbar is a metallic strip or bar that conducts electricity within a system. It serves as a central point for the distribution of electrical power to various components, such as batteries, motors, and other electronic devices. In the context of an electric car, a laminated busbar is designed to efficiently and safely distribute electrical power within the vehicle's electrical system. It can handle the high currents and voltages associated with electric vehicle powertrains. The laminated construction helps manage heat dissipation, reduces electrical losses, and provides a compact and lightweight solution.

- Insulation resistance20M Ω DC/1000V

- Parasitic inductance15nH/m

- Temperature rise≤30K

- Working temperature-40~105℃

Features of laminated busbars:

- High current density: Laminated busbars can carry a higher current density than traditional busbars, which makes them more efficient and space-saving.

- Low inductance: Laminated busbars have low inductance, which means that they can reduce voltage drop and improve power quality.

- Good flexibility: Laminated busbars are more flexible than traditional busbars, which makes them easier to install and route.

- Corrosion resistance: Laminated busbars resist corrosion, making them suitable for use in harsh environments.

- High strength-to-weight ratio: Laminated busbars have a high strength-to-weight ratio, which makes them lightweight but strong.

Applications of Laminated busbars

Laminated busbars are used in a variety of applications, including:- Power distribution: Laminated busbars distribute power in various electrical systems, including switchgear, panelboards, and motor control centres. They are particularly well-suited for applications where high current density, low inductance, and good flexibility are required.

- Power conversion: Laminated busbars, such as inverters and converters, are used in power conversion applications. They are used to connect these devices' input and output terminals, and they help reduce voltage drop and improve power quality.

- Transportation: Laminated busbars are used in various transportation applications, including electric vehicles, hybrid vehicles, and locomotives. They connect the battery, motor, and other components of these vehicles, and they help reduce weight and improve efficiency.

- Renewable energy: Laminated busbars are used in renewable energy applications, such as solar and wind power systems. They are used to connect solar panels or wind turbines to the grid and help reduce losses and improve efficiency.